Macpenny Mist Propagation Equipment

Macpenny Mist Propagation equipment, with over 40 years experience and manufacturing, is the most respected name in this field.

The installation of a Macpenny system in the propagation house leads to an immediate and dramatic increase in plant production efficiency.

A range of system controls are available, to suit all propagation needs.

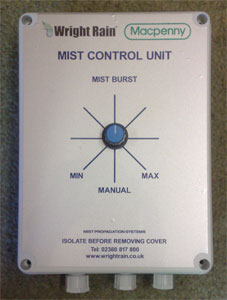

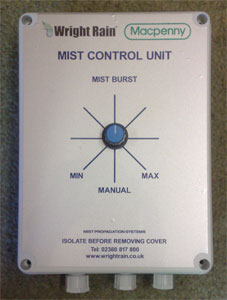

Mist Control Unit

This is a simple control system designed to automatically provide the optimum mist condition for the rooting of cuttings. Consisting of a Mist Control Unit linked to an Electronic Leaf moisture sensor, the unit operates automatically by changes of moisture on the Electronic Leaf. The unit can be adjusted to give mist burst of durations from around 3 to 10 seconds, the option of a manual override provides for a continuous mist if desired. The Control Unit is manufactured in house to our exacting quality standards. Although a commercial controller this unit will appeal to the keen enthusiast market due to its cost and ease of operation

Available in 240VAC & 110VAC

Electronic Leaf

Positioned amongst cuttings this unit is a moisture sensor which determines the frequency of misting. Moisture on the surface of the detector carries a current between its two electrodes. When the water has evaporated the circuit is broken, sending a signal to the Mist Control Unit, causing misting to commence. The Electronic Leaf is supplied with a choice of 2.5m, 5m or 10m cables to suit the individual bench requirements.

Macpenny Precision Mist Jets

The result of extensive development and careful design, this atomiser jet is suitable for a wide range of uses. Precision made of brass, with a stainless steel striking pin. The jet is produced in four sizes to suit the individual bench width.

The jet incorporates an 80 mesh filter capable of stopping even the finest particle from interfering in the nozzles operation. Each jet can be isolated from the rest of the system by inserting a rubber disc or similar under the striking pin and screwing down the adjusting nut.

Technical:

- ½” BSPM thread

- 1m standard spacing for all nozzle sizes

- Operating pressure 3-4bar (satisfactory results can be achieved at a lower pressure)

- Jet output can be varied + or – 25% by adjusting the striking pin clearance.

- Nozzle Sizes:

- No.1 1m throw 15.9lph

- No.2 1.2m throw 27.2lph

- No.3 1.4m throw 36.4lph

- No.4 1.5m throw 54.6lph